Beyond the big switch

The Evidence

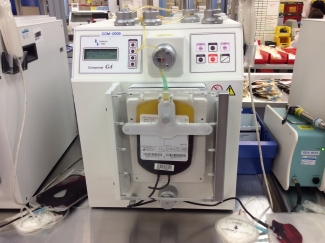

A Quality Monitoring Program (QMP) was established through which research and development expertise is applied to the continuous monitoring and improvement of products and processes at Canadian Blood Services. Manufacturing has been investigated deeply and procedures have been assessed for their value. Efficiency has been increased by elimination of unnecessary steps, including mixing and balancing of whole blood before centrifugation. Centrifugation settings and CompoMat® cycle times have been optimized and improved. Most importantly, our research has demonstrated that these changes have been made while maintaining or even improving product quality

The Impact

For Canadian Blood Services, this research has allowed us to confidently improve our manufacturing processes with the knowledge that product quality is not compromised. It has deepened our understanding of our blood products, and outputs include a growing product characterization dataset that goes beyond regulatory requirements and is an invaluable resource for anyone who needs to better understand “what is in the bag?” International partnerships have been established through the QMP to begin to evaluate the impact of different manufacturing processes on product quality, and to expand product benchmarking internationally.

The QMP project is led by Craig Jenkins.

(See Research highlight March 2015)